PRODUCTS |

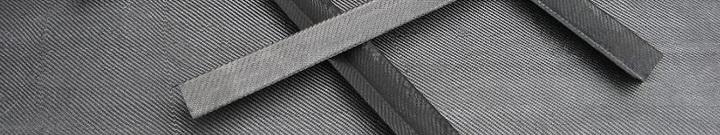

CFC Sheets/PlatesCarbon fiber composite (CFC) is a relatively new material which, by virtue of being chemically inert, and having additional advantages of high strength, light weight and thermal resistance, is finding increasing industrial application.

CFC is suitable for use as hot face linings in pressure quench furnaces offering maximum insulation protection, and hence, package lifetime.

Its high strength-to-weight ratio makes it the ideal choice for structural assemblies and fixtures for work-piece support in vacuum, sintering, HIP, and semiconductor furnaces. Typical designs can yield greatly increased charge capacities of between 30 and 50%.

High density, high strength fastener grade materials are ideal replacements for graphite and molybdenum fasteners.

Application ranges up to 2800 °C with inert gas or vacuum. Advantages are: extremely low wall thickness, reduction of thermal mass and consequently, a reduction in the energy utilized, reduction of cycle times. Furnace is easier to service, because the retorts can be removed from the furnace by hand.

We can supply different kinds of CFC furnace fixtures and other structures in custom shapes and dimensions too, made from CFC sheets/plates. This material can also be used as protective surface on graphite board insulation. CFC exterior shells provide a robust barrier, protecting the insulating core from damage by dropped parts, melt splatter, or high velocity particle abrasion.

Available Sizes and Main Properties

Characteristics and Benefits

Applications

|

||||||||||||||||||||||||||

|

NOBORAN LTD Miskolc, Hungary info@noboran.com |

|||||||||||||||||||||||||||